Hydraulic Milling Vise

We are experience Hydraulic Milling Vise manufacturer, supplier, exporter, factory in Taiwan. Due to better satisfy the needs of customers, we will keep on promoting our skills of products and good service to all of them.

Hydraulic Milling Vise

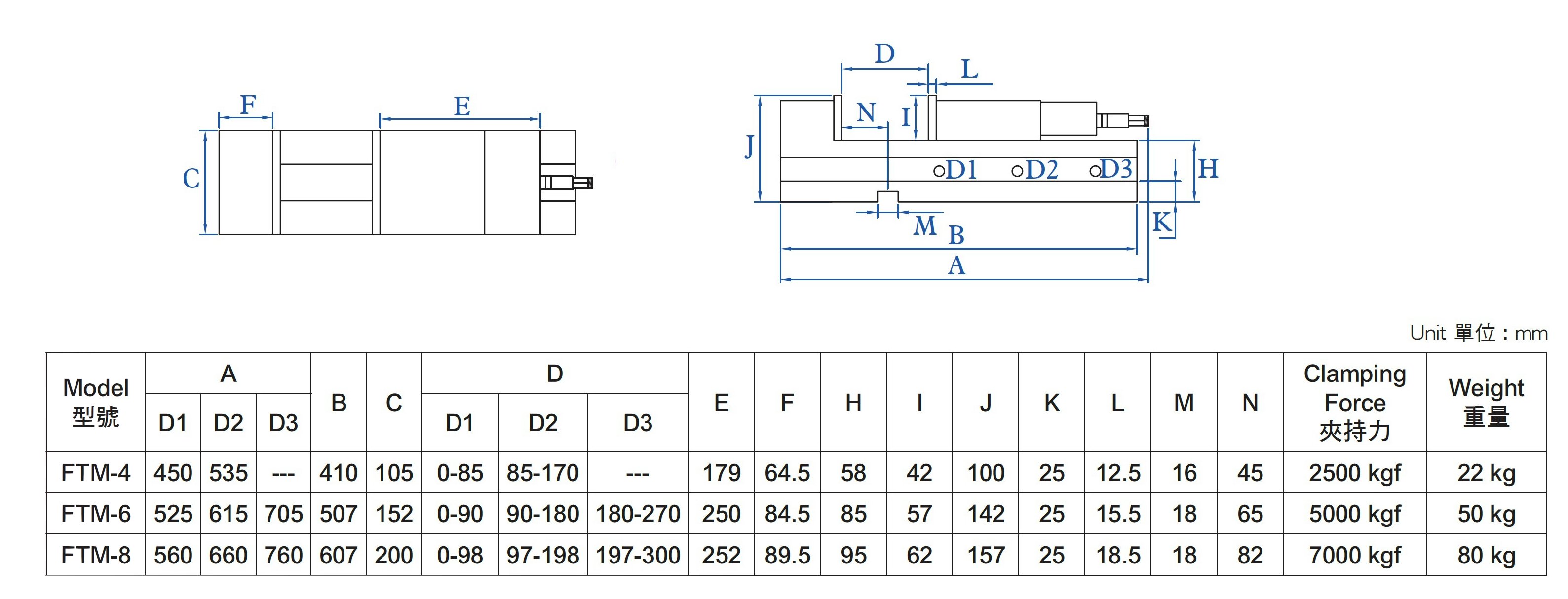

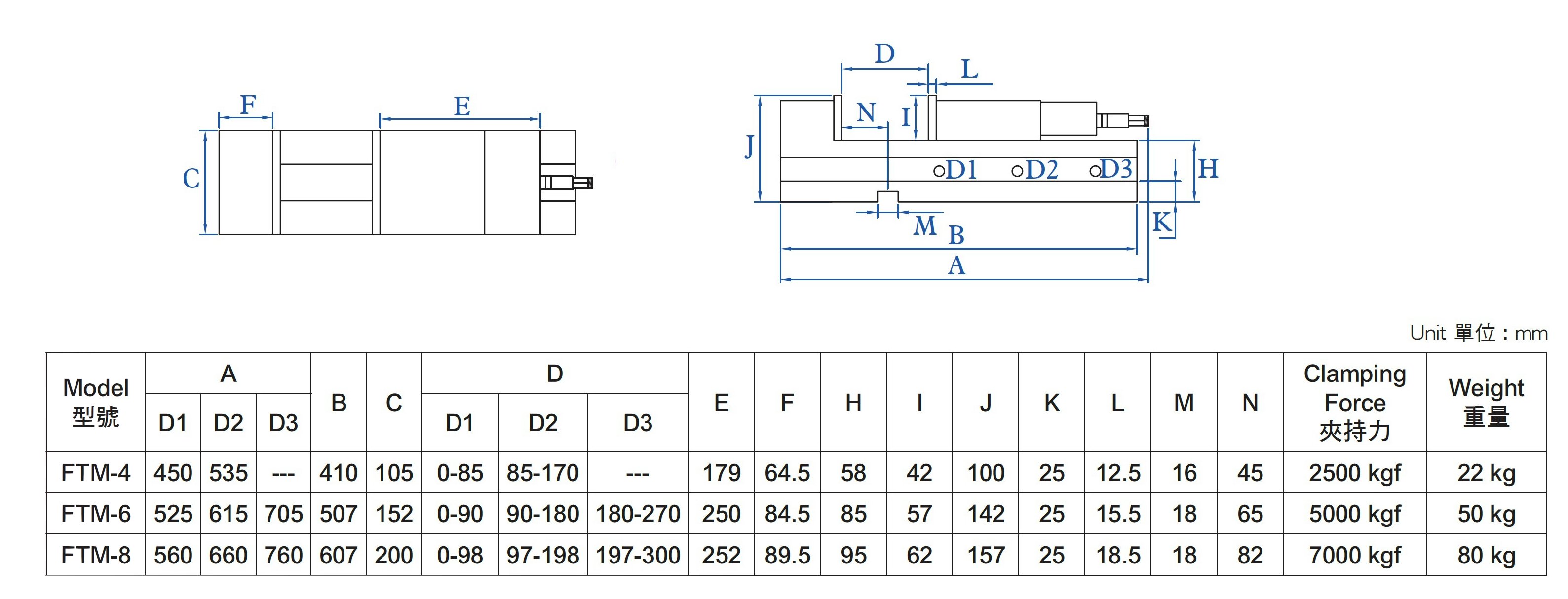

Model - FTM

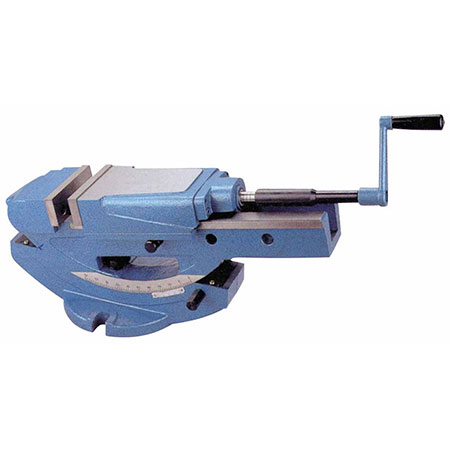

Hydraulic Angle Lock Vise

- Vise body is made of ductile iron FCD60.

- Down thrust with "semi-sphere" to prevent work-piece lift.

- Vise can side-lock to work.

- Vise slide-chunk can take out, Convenient to clean away chips and inside of vise.

We have our own manufactory, and accept OEM order, the professional production staff who will look after your

Hydraulic Milling Vise

and make sure you achieve the highest quality available for that product.Enquiry Now

Products List

Mechanical Power Vise

Delicately designed structure, ensures working precision and enhances rigidity for long service life.

Fast switch and high compatible module.

Front chip cover equipped to protect leadscrew from swarf.

Rear chip cover adopted, prevents chips getting into the vise.

Powerful Backward Clamping Vise

Backward Clamping Vise, it's ergonomics for easy reach, thus saves time and prevents back strain

Delicately designed structure, ensures working precision and enhances rigidity for long service life.

Fast switch and high compatible module.

Special patented system, conducive to amplifying and stabilizing pressure.

Mechanical Type Power Vise

The body of the MPV double force vise adopts a vertical rib structure to enhance the bending resistance of the body. The cast iron with good ductility is selected.

Hidden floating prevention mechanism reduces the floating rate of workpieces.

The working surface and the sliding surface of the movable body are heat-treated, the hardness can reach 45 degrees or more HRC, and the wear resistance is high.

Magical Jaw Vise

Multiple Jaws fit many different processing needs, and can clamp workpiece in any shapes including round, polygon and angularity.

Vise Jaws made of S-50C under HRC-55˚ heat treatment. (soft jaw is also available)

Vise maximum clamping force is 1200kgf

Magical Jaw Vise (Aluminum Jaw)

Multiple Jaws fit many different processing needs, no matter what shape of working piece, such as square, round, cylindrical or any irregular shapes, it can be clamped quickly.

Aluminum Jaw.

Vise maximum clamping force is 1200kgf

Magical Jaw Vise (Acrylic Jaw)

Multiple Jaws fit many different processing needs, and can clamp workpiece in any shapes including round, polygon and angularity.

Acrylic Jaw- non-conducting .

Mulaiple function Vise Changeable Mouth

Vise maximum clamping force is 1200kgf

Repositionability Magical Jaw Vise

Multiple Jaws fit many different processing needs, and can clamp workpiece in any shapes including round, polygon and angularity.

Re-positionability clamping.

The jaw width is 127mm, and maximum opening is 140mm.

Swivel Vise With Universal Clamping

Table 360° swivel.

45° tilt to front, rear, and right.

Suitable for all kinds of slant processing, drilling and milling, etc.

This vise associated with a swivel base can clamp workpiece in any shapes including round, polygon and angularity.

High malleable casting iron.

Vise maximum clamping force 1200kgf

Hydraulic Vise

Constructed with Hydraulic Cylinder, which absorbs cutting vibration and improves the precision of machining whilst maintaining a high clamping force.

Vise Body is made of high tensile cast iron. The Sideways are hardened and ground to ensure rigidity, durability and minimal deformation.

Clamping ranges design:Quick to change and easy to operate.

Powerful Angle Lock Vise

Body has one-piece construction for high rigidity and precision.

Angle-Lock Mechanism provides downward pressure on Jaw to ensure parallel clamping.

Both surfaces of Slideways are heat treated.

Large opening capacity up to 300mm.

Slant Type Built-in Hydraulic Vise

Tilts up and down.

High quality casting with ground finish.

Easy and light operating, 3 holes can be firmly clamped quickly.

Type AHT-6 jaw’s opening 300mm, 2 times larger than the normal milling vises.

It is particularly well suited to many jig and fixture making applications as well as being more versatile for general machining work.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk