Vice Stopper

FAMOUS CORPORATION is a major manufacturer, supplier, developer and producer of high quality Vice Stopper. We aim to produce products with high standard of quality, style, technology, and innovation. This is achieved by using only the best raw materials, experienced engineers, and production facilities available. And we guarantee to provide you these products to overseas markets with high quality and competitive price. Our good quality and our professional service are appreciated by customers from many countries, if you are interested please free to contact us.

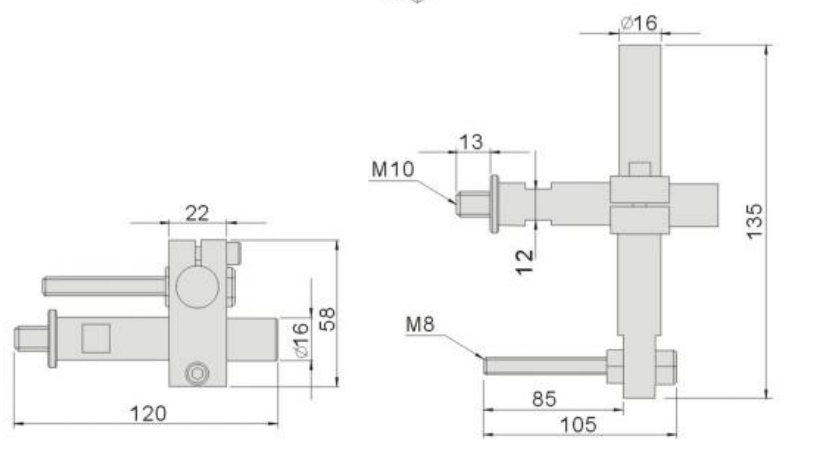

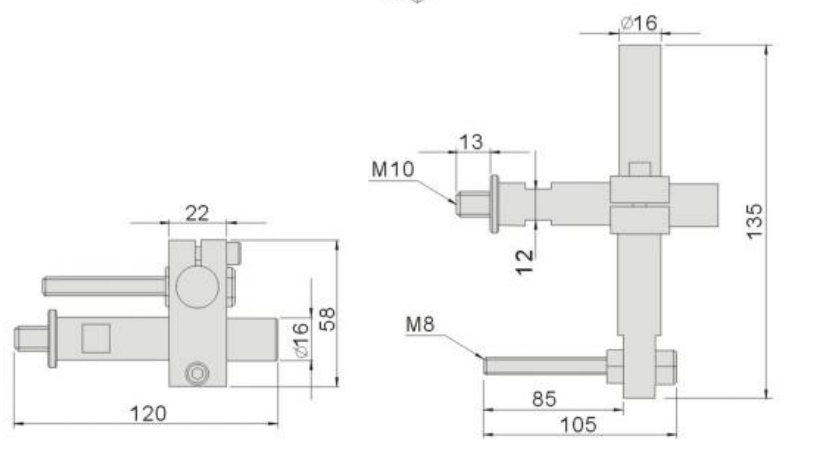

Vice Stopper

Model - VWS

Vise Workpiece Stopper

- Vise Workpiece Stopper VWS can be mounted at the positions provided on both sides of the vise.

- Fastening thread M10

- Vise Workpiece Stopper can be used for precision vise, such as Precision Vise NCV, Mechanical Power Vise PCV-6, Powerful Backward Clamping Vise PRC…etc

Our main products is

Vice Stopper

. Adhering to the "good faith" principle of service, "mutual benefit" principle of cooperation, strictly check quality, adhere to the "norms" of corporate thinking, we hope have sincere cooperation with friends from all walks of life and go hand in hand.Enquiry Now

Products List

Guide Key

Vise Accessories-Guide Key

Material: S45C

Surface finish: Black Oxide.

Accuracy: ± 0.01/100mm

Application︰Ground surfaces provide accurate of positioning inside of T-slot and vises.

6 Models: KY1812, KY1814, KY1816, KY1818, KY1820, KY1822

Vise Locked Block

Vise Accessories-Vise Locked Block

Material: S45C

Surface finish: Black Oxide.

4 Models: VC15(for X-3 and DX-3 series), VC22(for Precision Vise NCV type), VC23(for Mechanical Power Vise MPV type), VC25

4 pieces per set

Prussure Gauge

Pressure gauges are common measuring instruments and are widely used in various fields.

It can visually display the pressure changes in each process step.

For regular checks of the clamping force of hydraulic vise, pneumatic vise, and mechanical vise.

3 Pressure Range: 0-1 ton, 0-5 ton, 0-10 ton

JAWS

Jaw-1. Standard Jaw

Jaw-2. Soft Jaw

Jaw-3. Back Jaw for achieving large clamping width

Jaw-4. Step Jaw

Jaw-5. V Jaw for horizontal and vertical clamping of workpieces

Jaw-6. Cross Grooved Jaw for the safe clamping of workpiece exceeding the stand jaw width, used in pairs only

Jaw-7.~8. V Jaw

Jaw-9. Aluminum Jaw

Jaw-10. Acrylic Jaw

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk